1. Introduction

The Alicia de Larrocha Foundation[1], devoted to pianist Alicia de Larrocha (Barcelona, 1923-2009) holds a valuable collection of private audio recordings, mostly non-commercial live concerts and interviews which covers over 60 years.

Following IASA guidelines, more than 500 compact cassettes of all brands and types have been recently catalogued and digitized (04/2013 – 07/2014). Although most carriers were in good optical and mechanical condition and allowed for proper transfer, around 2% of them presented severe degrees of tape-to-head sticking and squealing (“stick-slip[2]”) which resulted in a well-known array of problems:

the frequency modulation (FM[3]) of the original audio carrier which causes, depending on its extent, from a wobbly flutter effect to complex non-linear frequency sidebands (high frequency artefacts) that cannot be removed once in the digital domain[4] a progressive decrease in the original signal level, specially at high frequencies (low-pass filtering) increased tape-to-head tension and friction that slows down and eventually stops the deck playback transport.

Such problems are as a whole the result of the so-called Soft Binder Syndrome (SBS)[5] to substitute what was formerly known as Loss of Lubricant (LoL).

The goal of this article is twofold:

- to review key theoretical aspects of SBS as a result of FM distortion and analyse its effects on the digitized frequency response of some affected cassette tapes

- to present a practical implementation for individual tape re-lubrication which, based on past reported experiences[6], sometimes combined with cassette shell re-housing, has given good results for renewed playback and digitization in the short and midterm.

This re-lubrication proposal is based on a standard tape transport speed-controlled with an Arduino[7] motor shield processor which is able to provide continuousand even lubrication to tape as it travels in an external path around a rotating foam drum flooded with cyclomethicone, a volatile siloxane that completely evaporates with time. Playback equipment for the re-lubricated tapes (Nakamichi CR-7 and ZX-7) remained undamaged in the mid/long term.

2. SBS, SSS, LoL: the problem and the terminology in context

“Soft Bynder Syndrome” is broadly accepted as a catch-all phrase to describe several problems related to hydrolyzed polyester urethane binders (including lubricants) and consequently to different and faulty tape behaviours.

- SSS (“Sticky Shed Syndrome”), mostly referred to polyester back-coated tapes that may show any combination of stickiness, shedding and/or squealing that can be temporally reduced by backing (aka tape incubation)

- LoL (“Loss of Lubricant”), a term being historically applied to polyester-based tapes that will squeal due to the stick-slip traction provoked by stickiness, but mostly without oxide significant shedding, and which do not respond positively to backing.

It has been shown that, in normal conditions of use and storage, magnetic tape is not prone to lose its original amount of lubricant, even though exhibiting SSS or SBS. Following Hess terminology, the FACET document proposes SBS-UP (Soft Bynder Syndrome – Unidentified Problems”) as a way to particularly refer to this formerly misunderstood “Loss of Lubricant”.

Analogue cassette tape (from 1963 on) may exhibit this SBS-UP (and not SSS) due to the following facts:

- polyester urethane binders were used

- although it is always polyester based, tape was not back coated (coating being closely related to SSS)

- tape may show stick-slip and squealing problems, but not oxide shedding

- reportedly[8], cassette tape has never responded positively to incubation

Once discarded incubation as a temporal solution, and also dismissed the actual loss of the lubricant as the main reason for SBS-UP, which approaches are left?

2.1. Cold playback

Instead of acting on the tape, Hess and others propose to adapt the environment for a controlled cold playback, were low temperature -below the so-called glass transition temperature Tg- would reduce stick-slip noise modulation. In favour of this approach there is the experienced fact that SBS increases with working temperature, that is, after the reproducing machine has achieved its normal working temperature (which may be especially high in cassette decks). The author has not yet tried or found any case-studies of this approach specifically applied to cassette tapes and players, but it has been tested by Hess on open-reel tapes[9].

3. Lubrication, again

Discounting actual loss of the original lubricant, its degradation or failure to work as intended might be one of the reasons for a failure playback. Based on re-lubrication, temporal solutions have been devised to reduce friction by temporally smoothing tape-to–head wear while minimizing spacing losses (HF response decay).

Re-lubrication should then be considered not as a way to compensate for a material loss, but to recover the ability of transporting the tape smoothly through its path.

Several lubricants have been reported as possible candidates[10], among which the author considered two

- jojoba oil, a 100% vegetable oil obtained through cold pressing of the seeds of the Simmondsia chinensis

- cyclomethicone pentamer, a volatile, non-greasy, low viscosity silicone oil (also known as known as decamethyl, cyclopentasiloxane cyclopentasiloxane)

Cyclomethicone has been preferred for the following reasons

- the existence of previous successful experiences, specifically on cassette tapes[11]

- no need of dilution with isopropyl alcohol, which reportedly swells the binder and makes it softer[12]

- the assurance of volatility after a certain amount of time, which means that the silicone will fully evaporate in the mid-term, long after digitisation has been made possible

Cyclomethicone and Jojobal Oil

This final point must be overstated, as any additional lubricant won’t be absorbed by the binder and thus should be removed, spontaneous vaporization being the ideal solution.

4. Practical implementation

As the total amount of cassettes affected by SBS in the Alicia de Larrocha Archive wasn’t critical, a simple, one-at-a-time method for cassette tape re-lubrication was devised to allow for a motorized, smooth, uniform application of the lubricant over the whole tape width and length outside the cassette deck, avoiding the need of electromechanical modifications.

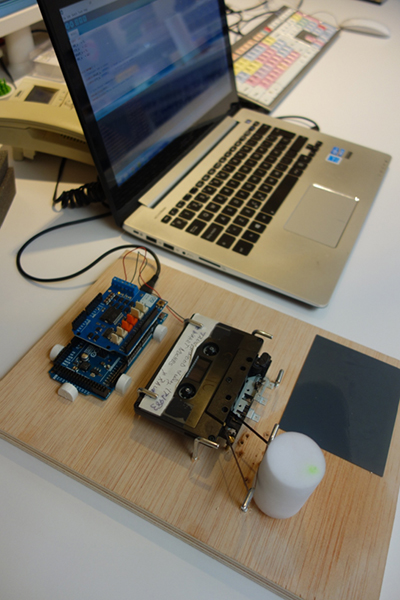

A propotoype was built based on the following elements

- an Arduino Due[13] microcontroller board + Arduino motor shield processor

- a standard cassette tape transport (motor included) un-mounted from a portable cassette player

- a rotating foam drum flooded with cyclomethicone, able to lubricate tape continuously and evenly as it travels in an external path

The actual implementation could not be simpler: the Arduino microcontroller is programmed through a computer laptop to control the rotating time, speed and eventually direction of the standard transport motor (real-time forward playback speed used). The foam drum is heavily flooded with the synthetic lubricant and remains fully wet throughout the length of any tape; being lightly-weighted, it sticks to tape and rotates along by static friction on its axis, avoiding the need for a synchronic motor.

Image 2. Re-lubrication device prototype

The prototype, mounted on a soft plywood board, allows for adjustable pins or hooks to specifically house any cassette and provide the easiest and smoothest path around the foam drum. When needed, a specific pin is oriented towards the pinch roller to add a slight pressure in order to maintain tape-to-roller contact for steady tape transport. Actual behaviour can be seen on the following video:

(in case your browser does not support embedded viewing, please click on Video re-lubrication prototype)

Such a solution avoids the need to extract the tape from its cassette shell to apply re-lubrication, so welded shell tapes (with no screws) are not damaged.

Affected tapes

The following table shows actual tapes (brands and types) found with severe degrees of SBS-UP. Their production years significantly coincide around 1970-1980.

Cassette brand

BASF SM cassette LH super 120

Philips SuperFerro High Output LN C-90

Philips SuperFerro High Output LN C-90

TDK Low Noise C120

BASF SM cassette LH super 90

AGFA-GEVAERT C90+6 HIGH DYNAMIC

Scotch C-90 Extended Range Low Noise High Density

unknown – unbranded

Philips Super Ferro floating foil SECURITY High Output LN

Production years

1974-75

1978-81

1978-81

1975-78

1974-75

1975-77

1971-73

1987-81

Type

Type I

Type I

Type I

Type I

Type I

Type I

Type I

Type II

Type I

Problem

squealing tape (stick-slip)

squealing tape

squealing tape. Progressive HF signal loss

squealing tape

squealing tape wow&flutter cassette stops. too high tape

tension and friction at the tape head

squealing tape wow&flutter could not be rewound/played back

severe wow

increasingly squealing tape

Diagnosis

SBS

SBS

SBS

SBS

SBS

SBS?

SBS

SBS

SBS

Table1. List of tapes from the ALicia de Larrocha Archive affected by SBS

6. Case reports. Frequency analysis and re-lubrication results

Re-lubricated tapes were played back and digitized within the next 24 hours to ensure action before lubricant evaporation. Results were satisfactory in all cases, even though a second pass was needed for the cassette tape corresponding to Case 1.

Two study-case examples, Case 1 and Case2, can be heard here:

CASE 1 – pre-lubrication

CASE 1 – post-lubrication

CASE 2 – pre-lubrication

CASE 2 – post-lubrication

No post-production processes were applied whatsoever.

6.1. Case 1: a fragment from Tape nº7 (Table 1)

As sonic and graphical evidence, we will analyze a 75 seconds sample of the Chopin Piano Concerto nº2, played by Alicia de Larrocha with Orquestra Ciutat de Barcelona (former OBC) conducted by Antoni Ros-Marbà on April 17, 1971 (live recording). The sample was recorded in tape nº7 (see Table 1).

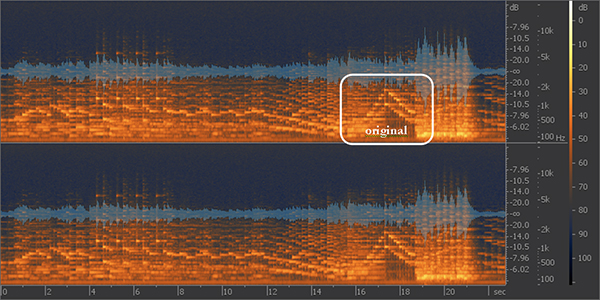

The following figures show the sonogram and the superimposed waveform of this musical passage, pre and post re-lubricated. Vertical axis shows frequency in a logarithmic scale. Beyond the extended high frequency noise along the timeline, highlighted high frequency modulated sidebands are specially revealing. Such inter-modulated ascendant and descendant artefacts are the side effect of a musical phrase where the solo piano plays ascendant and descendant scales. Such artefacts largely disappeared from Figure 2.

Figure 1. Case 1 pre-lubrication spectral analysis

Figure 2. Case1 post-lubrication spectral analysis

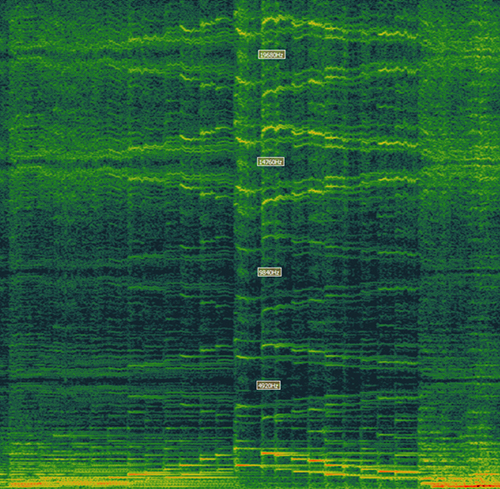

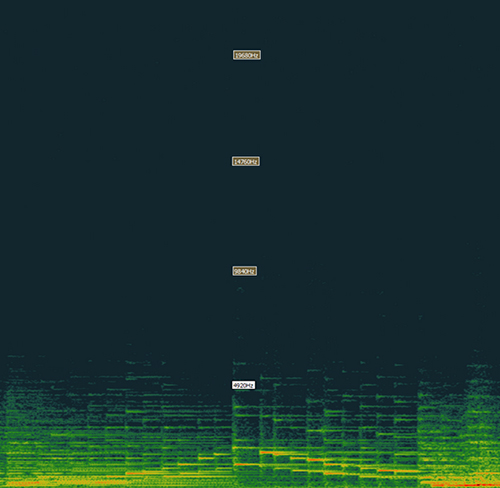

Figures below allow for a closer look at a linear-scale sonogram[15] of the same musical fragment. Figure 3 reveals several side band replicas of the original content (centred at fc) at frequencies fsb = fc±nfm (where n=1,2,3…) and spaced at multiples of fm.

Based on analysis of the sonogram data, the original baseband –the spectrum of the original audio carrier – is frequency modulated by the stick-slip distortion at an approximate modulation frequency of fm = 4920Hz (a period Tm = 0,203ms).

A mild stick-slip distortion would result in a scrape flutter (musically speaking, a wobbly vibrato, as can be heard in Case 2), whereas severe distortion (high amplitude stick-slip as in Case 1) will generate a very complex spectral pattern.

Figure 3. Case1 pre-lubrication. Baseband and FM modulation at multiples of around 4920Hz

Figure 4. Case 1 post-lubrication. Baseband without traces of FM modulation

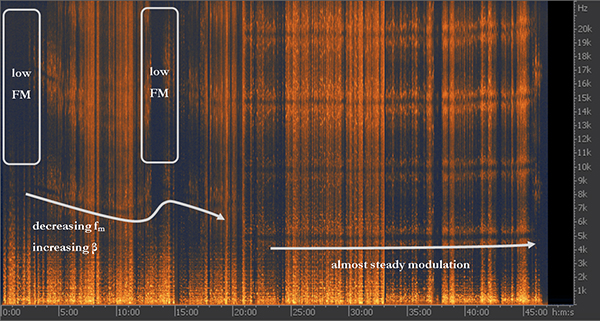

6.1.1. The evolution of FM distortion during playback time

It can be also interesting to analyze the evolution of the modulation frequency thorough the length of this particular tape number nº7 (45min per side – see Table1). This will be related to the ability of the original lubricant to provide smooth tape transport as much as to related mechanical factors such as the tape-to-head friction, the tape tension, the sturdiness and stability of the tape transport, the working temperature of the cassette deck, etc.

The next figure traces the evolution of FM distortion, very low at the beginning, varying during a certain amount of time (see the initially wavy pattern for fm) but finally severe and roughly constant. In any case the distortion cannot be supposed constant throughout the tape, as for instance modulation distortion is quite low and inaudible between minutes 0:00 and 02:30 as well as between 13:00 and 14:00, but almost constant and steady from around minute 23:00 on. As expected, passages with no recorded sound imply no FM distortion.

Figure 5. Case1. Evolution of the modulator frequency fm through time. Pre-lubricated tape #7, side A, chanel left (mono)

FM theory states that the extent of the distortion index (in our case, the stick-slip effect) will depend on the modulation index β, which in turn depends on the modulator frequency fm and the carrier’s peak frequency deviation ∆fc (the latter depending on the modulator’s amplitude Am). The modulation index will also define the modulated signal bandwidth (BW), that is, the extent of the side-bands throughout the spectrum[16]. These main relationships are compacted in the following equations:

- The modulation index

- Carson’s bandwidth rule

We can deduce from these equations that, the lower the modulator frequency fm,

- the higher the original tape-to-head friction and the greater the potential tape damage due to excessive tension build-up

- the higher the modulation index and so the deeper its audible effect

- the higher the bandwidth of the modulated signal and so the more difficult to filter out by conventional means in post-production

Even though not readily visible in the sonogram, the extent of the carrier’s frequency modulation ∆fc (that is, the stick-slip amplitude) is the main consequence of this increased tape-to-head friction and thus the increased modulation index β.

6.2. Case 2: a fragment from Tape nº5 (Table 1)

Even though overall improvement in sound quality was consistent after re-lubrication, some drawbacks were detected:

- after a second-pass re-lubrication, a slight decay in HF response was audible, even with some drop-outs, due perhaps to excessive distance loss[17]. Such drop-outs were reparable in the digital domain, but eventually disappeared during a second playback

- continuous playback of re-lubricated tapes on the same tape deck, a Nakamichi ZX-7[18], eventually affected tape transport which resulted in a temporal playback failure that lasted for one week. After extended intervals with the device switched on, to maintain internal temperature and favour lubricant vaporization, the deck recovered normal function[19]

6.4. Four months after re-lubrication

In order to verify lubricant vaporization, an informal playback test was conducted four months after re-lubrication. As expected, all tapes exhibited varying degrees of the original SBS problem, a fact that confirms re-lubrication only as a temporal solution for proper digitization.

7. Conclusions

Discarded backing for cassette tapes with SBS, as also any digital means of sound restoration at a post-production stage due the complexity of the distortion pattern, re-lubrication has shown promise as a way to deliver -albeit temporally- playable cassette tapes to digitise.

When planning and implementing a prototype to allow for re-lubrication, care has been taken to ensure the following aspects:

- added lubricant agents should decrease tape-to-head friction without significant increase of spacing loss (HF loss)

- being a temporal solution, lubricants should vaporize from the tape and tape deck in the short or mid-term without causing damage. Nonetheless, the tape deck might result over-flooded with lubricant and become temporally non-operative

- lubricants should be applied evenly and uniformly along the tape length (not using manually applied q-tips) with a motorized, externally-controlled transport for duration and speed (that was implemented in our case with an Arduino microcontroller)

- tape transport should be done in the least obtrusive way, keeping tape within its cassette (be it the original one, or after removing tape to a new cassette shell)

- future improvements in the propototype should include guide rollers to reduce friction along the tape transport

__________________________________________

I’d like to thank Elena Elía and Maria Ferré, curators from the Alicia de Larrocha Archive, as well as Alicia Torra de Larrocha, for their kind support and permission to investigate and show practical examples of tapes with SBS. I’m also indebted to Paul Poletti, Perfecto Herrera and Enric Guaus, professors from the ESMUC Sonology Deparment, for reviewing the drafts of this document. I’d finally like to thank Margarida Ullate, Marcos Sueiro and Ferran Conangla for their encouragement to write this document.

8. References

Hess, R.(2007): “Tape Degradation Factors and Challenges in Predicting Tape Life” – http://www.richardhess.com/tape/history/HESS_Tape_Degradation_ARSC_Journal_39-2.pdf

- Casey, Marc (2007): “FACET – The Field Audio Collection Evaluation Tool”. Indiana University – http://www.dlib.indiana.edu/projects/sounddirections/facet/facet_formats.pdf

- Schüller, D. (2014:32-42): “Magnetic tape stability: talking to experts of former tape manufactures”. IASA Journal nº42, January 2014

- IASA Technical Committee, Guidelines on the Production and Preservation of Digital Audio Objects, ed. by Kevin Bradley. IASA-TC04 Technical Committee, Second Edition (2009), http://www.iasa-web.org/audio-preservation-tc04

- Bruce Carlson, A. (2002): “Communication Systems”. McGraw-Hill, 4th

- Agilent – Spectrum Analysis Amplitude and Frequency Modulation – http://cp.literature.agilent.com/litweb/pdf/5954-9130.pdf

- Reid, Gordon (2000): Synth Secrets, Part 12: An Introduction To Frequency Modulation” Sound on Sound, April 2000 – http://www.soundonsound.com/sos/apr00/articles/synthsecrets.htm